Automotive

Beattys Driveline Technologies’ coverage and expertise within the automotive sector sets them apart as a clear market leader.

Beattys Driveline Technologies’ coverage and expertise within the automotive sector sets them apart as a clear market leader.

Beattys Driveline Technologies’ coverage and expertise within the automotive sector sets them apart as a clear market leader. Due to the long association and rapport established with vehicle manufacturers and their dealerships, Turret automotive specialists have been called on by well respected brands such as Nissan, Ford & Holden to problem solve and develop specific driveline solutions for their market needs. Beattys provides the Automotive industry a complete package with the Turret Technology team taking care of your automotive drive shaft repairs & servicing while Turret Componentry maintains a comprehensive inventory of replacement automotive drive shaft parts to suit all makes & models, both past and present. Recently added to our Automotive market offering is a full range of premium quality WIX Filters – we look forward to your enquiry.

Beattys Driveline Technologies supply & service all business types within the automotive market. We look forward to your enquiry.

Motor Vehicle Dealerships | Mechanical Workshops | Automotive Parts Resellers | Engine Reconditioners | Transmission Specialists | Capricorn Members

Experienced technicians will diagnose driveshaft or CV operating issues then rebuild and service as required, reinstating driveline to original specifications.

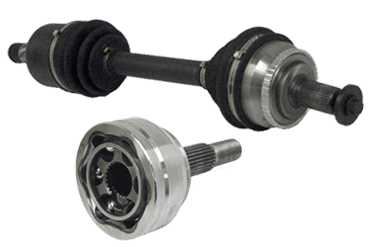

- CV Joints can be overhauled & refitted to shaft ends as an economical alternative to full replacement.

- Damaged or perished CV Boots will be replaced and reattached.

Utility vehicles and other four wheel drive models will feature front shafts with ‘double cardan’ assemblies as pictured above to cope with the high angle application. Beattys is very experienced in servicing and supplying spares for these shaft types and also offers complete replacement shafts for popular models such as Toyota Hilux. Enquire now for competitive pricing options.

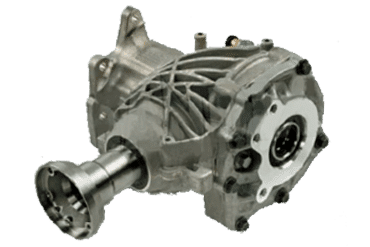

The unit shown above is a Volvo All Wheel Drive model transfer case or angle box. Due to mechanical issues the male spline on the crownwheel shaft was sustaining damage and premature wear. Turret Technology’s service team has the expertise and equipment to fully recondition these units including rebuilding spline and assembling with replacement bearings if required, resulting in a very cost-effective repair solution over against the expense of component replacement.

Automotive drive shaft repairs & servicing can be carried out on the full range of models available in the market today. Beattys’ comprehensive service package from component replacement through to major overhaul always includes lubrication and dynamic balancing of the complete driveline assembly. By choosing TURRET Componentry and servicing from the Turret Technology team vehicle owners can enjoy the peace of mind of industry-leading workmanship and quality while keeping maintenance costs down. Contact our Customer Services team today.

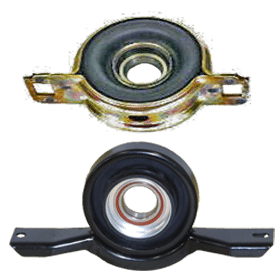

Beattys stocks a full range of high quality Centre (or hanger) Bearings. After fitment, driveline assembly should be dynamically balanced to recheck & remove any balance issues. View our Centre Bearing page for more information.

Check with Turret Componentry on the selection of CV Joints & associated parts on hand to support European, Asian, American and Australasian models. These units can also be overhauled as an economical alternative to full replacement. View our CV Joints & Shafts page for more information.

Another important wearing part, also known as ‘Donut’ or ‘Flexi’ couplings often used on the front end of automotive driveshafts to dampen torsional vibrations and compensate for misalignment. View our Rubber Couplings page for more information.

Here you’ll find an unparalleled choice of Universal Joints for fitment to all makes & models. Types include Internal circlip, External circlip, Combination & Staked. ‘Staked-in’ universal joints need press fitting with special tooling. View our Universal Joints page for more information.

View the componentry page for details on the complete range of driveline parts

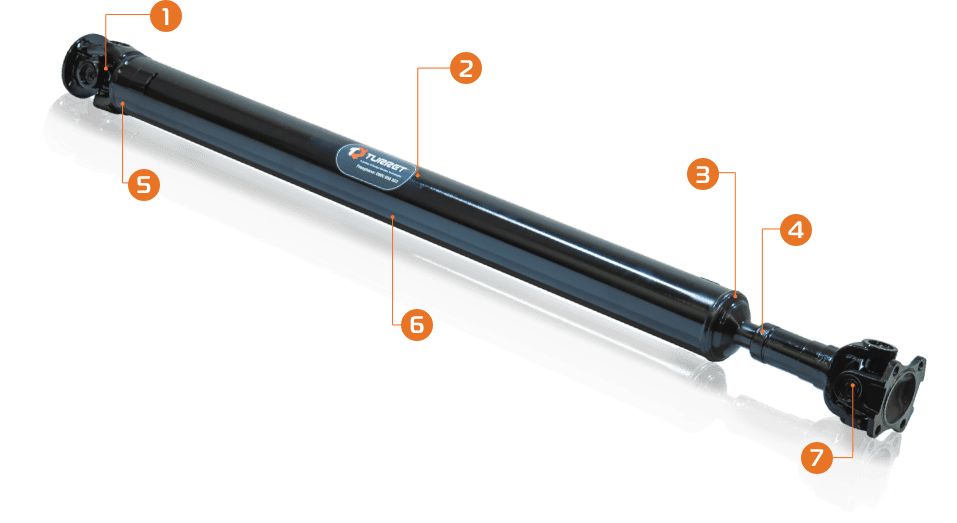

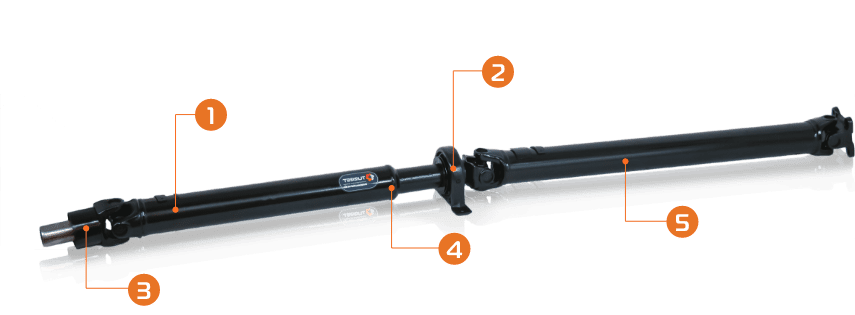

| 1. | Upgraded and reinforced yoke designs to prevent catastrophic failure. |

| 2. | All driveshafts are coated in a premium anti-corrosive paint to ensure they are protected from the elements throughout their life. |

| 3. | Premium automated welds allow for deep penetration and precise control while keeping consistency to a maximum. |

| 4. | Upgraded splines with increased spline engagement resulting in a more durable longer lasting driveline. |

| 5. | All driveshafts are balanced to ISO 1940 standard and balance weights are spot welded to prevent fracturing and stress on the driveshaft tube. |

| 6. | Replacement or upgraded driveshaft tube with thicker walls and larger diameters to allow for higher torque applications and increase the resistance to high shock loadings. |

| 7. | Internal circlip, external circlip and staked universal joints meet or exceed OEM specification and are fitted to factory specifications. |

Two Piece Drivehsafts

| 1. | All componentry and workmanship carried out to meet or exceed the original specification. |

| 2. | Full centre bearing assessments, repairs and replacements including upgrades to solid rubber types for better long term performance. |

| 3. | Standard and custom designed yokes and flanges to connect to any drive system. |

| 4. | Low noise and vibration free design. |

| 5. | Balanced as a two piece driveline for maximum accuracy. |

© 2025 Beattys Driveline Technologies Ltd. Website design by Hum Interactive.