Heavy Transport

The Heavy Transport and Logistics industry is a key player in our economy bringing the world’s goods to our door.

The Heavy Transport and Logistics industry is a key player in our economy bringing the world’s goods to our door.

The Heavy Transport and Logistics industry is a key player in our economy bringing the world’s goods to our door and delivering both people and products to their destinations, locally and around the globe. Beattys Driveline Technologies knows how vital it is to keep these trucks, trailers and buses on the road and has been servicing this sector as a core market for many decades. Recently added to our Heavy Transport market offering is a full range of premium quality WIX Filters. Read on to find out more about our expertise and coverage for all your heavy transport driveline & filtration needs.

Inadequate or incorrect lubrication as well as excessive angles or torque loads can lead to conditions such as:

The Turret Technology team will assess UJ condition and replace as required to maintain optimal performance.

This service includes:

This is a ‘hotspot’ area to inspect & maintain at regular intervals as lack of lubrication or other factors can lead to:

The Turret Technology team when working on this section of your shaft will:

This sliding spline section will need replacement if:

Needs to be checked over for:

Turret Technology will straighten or replace this as required with special grade driveline tubing. This section can also be lengthened or shortened to suit modifications.

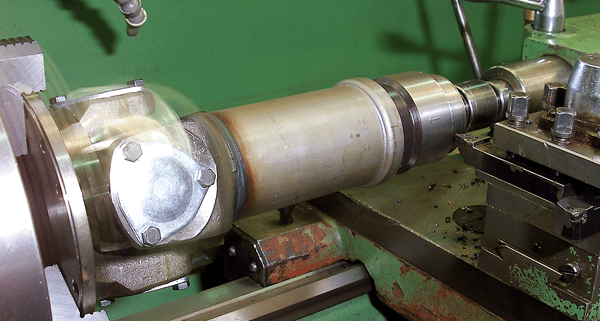

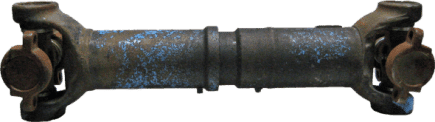

Typical Interaxle shaft repair sample: Wear in yoke eyes, u-joint failure, clearance in slip section causing vibrations

Same shaft: Now rebuilt, reassembled, lubricated as required and ready to go back into service

Yokes can become bent, damaged or even fractured as a result of excessive torque or shock loads. Wear in the yoke eyes can cause universal joint caps to rotate leading to premature failure.

The Turret Technology team will replace yokes that show up unacceptable for optimal operating performance.

This sliding spline section will need replacement if:

Inadequate or incorrect lubrication as well as excessive angles or torque loads can lead to conditions such as:

The Turret Technology team will assess UJ condition and replace as required to maintain optimal performance. This service includes:

Delivering Savings – Instead of being faced with the outlay of full OEM replacement, Turret Technology has the specialised equipment and technical know-how to repair, replace & upgrade the worn components delivering substantial savings and benefits.

Delivering Reliability – All componentry, processes & workmanship is of the highest industry standards and is trusted by commercial transport operators nationwide to deliver reliable performance day after day.

We can also manufacture complete new shaft assemblies to original design.

© 2025 Beattys Driveline Technologies Ltd. Website design by Hum Interactive.